pallet shrink wrap machine safety

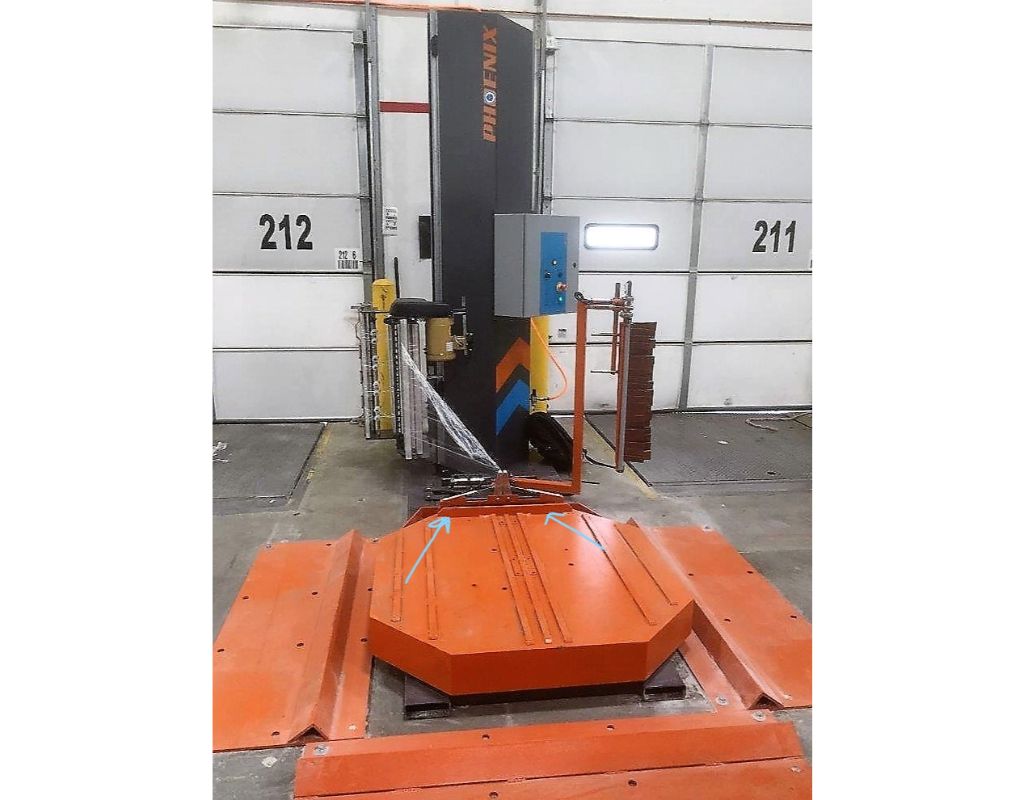

There should not be any protrusions damaged or leaking containers or bags no loose ends to each product and the loud on a pallet should be stable. When the machine is operating people should be a certain safe distance away from the turntable.

4 Types Of Common Stretch Wrappers Machines On The Market

The operator must stand in the front of the working screen you should away from the turntable.

. The heat guns used by Rhino Shrink Wrap incorporate a safety cut-out and dead-mans handle so that as soon as the operator releases the handle the gas and heat is immediately. From stretch wrap to labeling products and everything in between we have the supplies you need. The certified service technicians at Robopac USA can have most semi-automatic stretch wrap machines up and running in 30 minutes.

Before beginning the shrink wrapping process. Registered in England Wales No. The OSHA standard 29 CFR 1910212a1 General requirements for all machines states.

Operators must ensure other apparatus like forklifts and pallet jacks are liberated from turntable rotation. Office Higher House. Pallets that differ in weight and height can change the amount of film needed.

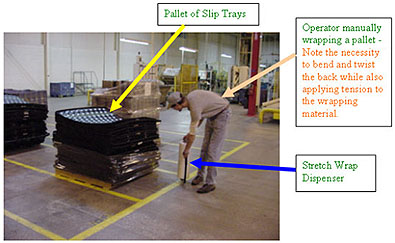

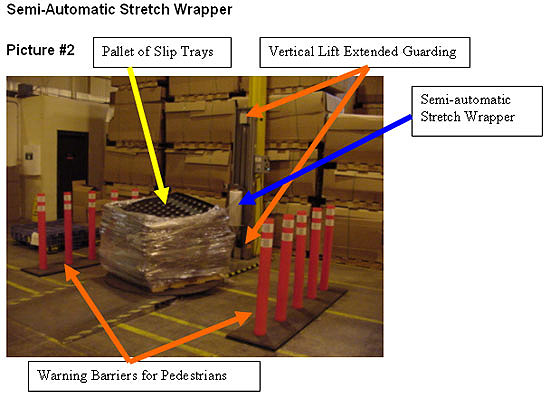

Most workers are happy to not stoop and circle a pallet of refrigerated or frozen foods but rather push a button and allow the machine to take over the task. Train workers to safely use the stretch wrap equipment. As ubiquitous as they are in loading dock areas where palletizing occurs there still arent specific OSHA guidelines regarding proper guarding of stretch wrap machinery.

Pallet shrink wrap machine safety Monday February 21 2022 Edit. Shrink wrapping materials and equipment. If these controls are.

Loose material and mechanical moving parts do not mix very well. Rhino is a registered trade mark of Triple Pillar Ltd. After the machine stops move closer to the machine remove the goods turn off the switch and cut off the power supply.

This is the first thing to do when using a pallet stretch wrapping machine especially when the goods are slightly larger. Goods that are being prepared to be shrink-wrapped into a single unit should be stacked carefully on pallets. 2783 Orion Shrink Wrap.

Risk Assessment Before Shrink Wrapping. Knowledgeable workers are safe workers. Currently these safety regulations for.

Over time pieces of stretch film chips of wood from pallets and trash will eventually find their way in and underneath the machine. Use a vacuum-sealing or shrink-wrapping device. The intent of vacuum packing is usually to remove oxygen from the.

First things first. Additionally under the Occupational Health and Safety Regulations 2017 an employer must so far as is reasonably practicable eliminate any risk of a musculoskeletal disorder MSD associated with hazardous manual handling. Shrink wrapping a pallet involves an entirely different film material that responds to heat to tighten around the load not tension pulled on the load as is the case during stretch wrapping.

The machine will apply the force to tie the pallet together and theres no need for your employees to move the film rolls from place to place. Unplug the machine from the power outlet and clean out any debris from around and under the pallet wrapping machine. Hand wrapping is also connected with repetitive motion injuries one of the most common safety hazards in the warehouse.

One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point-of-operations ingoing nip-points rotating parts flying parts flying chips and sparks. A pallet ˈ p æ l ɪ t also called a skid is a flat transport structure which supports goods in a stable fashion while being lifted by a forklift a pallet jack a front loader a jacking device or an erect craneA pallet is the structural foundation of a unit load which allows. Lets take a look at the operation guide during the use of stretch wrap machine.

Safety starts with knowledge and never ends. A stretch wrap machine eliminates these risks. Its vital to install stretch wrap machines correctly.

As with most other industrial processes what began as a manual operation the arduous task of bending pulling and moving stretch wrap around a pallet is now commonly automated. Stretch Wrap Machine Safety Guidelines During Operation. One of the best things about working with Robopac USA is that our team will help you install whatever stretch wrap machine you use.

For automatic stretch. Automated stretch wrap machines are one area of plant operation in which new regulations have not kept pace with new technology. Use a semi-automatic stretch wrapping machine.

Uline stocks a wide selection of safety guards safety rails and safety barriers.

Osha Stretch Film Pallet Wrapping Guidelines

Osha Case Study Replacing Hand Wrapping By A Semi Automatic Stretch Wrapper

Stretch Wrapper Safety Guide Handle It

Pallet Wrapping Machines How To Pick The Right One

Stretch Safe Machine Manual Pallet Wrap Machine Kite Packaging

Mobile Robotic Stretch Wrap Machine Handle It Inc

Quick Packaging News Free Pallet Wrapper With Airflow Vented Stretch Film Free Pallets Pallet Pallet Wrap

Noxon Ekko 90 Pallet Wrapping Machine Youtube

Mobile Stretch Wrapper Manual Pallet Wrapping Machine Kingfisher

Orbital Stretch Wrappers 5 Reasons To Change Your Process Ips

Rotating Arm Stretch Wrapper Model 2200 Handle It Inc

Wrapping Machines Tosa Group Leaders In The End Of Line Market

Osha Stretch Film Pallet Wrapping Guidelines

Pallet Wrapping Machines Starting At 5000 Handle It Inc

/f/120136/500x600/fd9b67c641/yps-homepage-our-solutions-stretch-wrapping-machines.jpg)

Stretch Wrapping Machines Yorkshire Packaging Systems Yorkshire Packaging Systems

Mobile Stretch Wrapper Manual Pallet Wrapping Machine Kingfisher